Sustainability is at the very heart of StePac’s modified humidity (MH) technology which we invented over two decades ago, integrated with modified atmosphere (MA) packaging.

In an era when the UN’s Food and Agriculture Organization (FAO) announced to the world that over 50% of global fresh produce perishes before it makes it to our plate, it is more relevant than ever to be part of the solution to prolong the viability of our global food resources. Our R&D’s postharvest and polymer laboratory are continuously developing the next generation of waste-reduction solutions for maximal shelf life of perishable produce with the greatest attention to environmental stewardship by ensuring reduced emissions and recyclability.

How can using something plastic actually do something good for the environment? With society’s call for reducing plastic waste, we need to keep in mind that this initiative might cause an even greater environmental problem: food waste. How can we balance creating plastic packaging that is as eco-friendly as possible, and at the same time keep produce fresh the longest?

StePac has done just that by developing modified atmosphere (MA) packaging coupled with modified atmosphere (MH) technology to enable shelf life extension of fresh produce. There is no doubt that we see excessive use of plastic in the industry. At the same time, we need to be sensible and not abandon it altogether, rather use it when we really need to, such as preventing food waste.

Food waste is responsible for approximately 8% of all greenhouse gas emissions. Functional plastic packaging is part of the solution for preventing this waste and eliminating it completely would result in even higher levels of food waste. This is why a more comprehensive approach is required.

StePac created the responsible, leaner, and sustainable approach. By harnessing modified atmosphere packaging and modified humidity technology, aging and ripening processes are slowed, nutritional value and flavor are retained and microbial decay is inhibited. The modified humidity properties of the film help reduce dehydration and weight loss, while helping avoid accumulation of free water in the packaging. The result: prolonged storage and shelf life of fresh produce reducing waste worldwide.

StePac promotes a four-pillar approach for lightening the environmental footprint of plastic packaging.

The principles are straightforward: Use plastic packaging only when it…

is truly necessary, such as to avoid food waste

produces net savings in greenhouse gas emissions

is as physically lean as possible

strives for a circular economy with mechanically-recyclable packaging. If mechanical-recycling is not feasible, adopt chemical recycling.

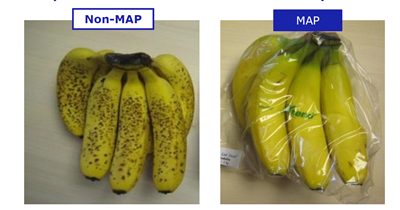

Did you know that a kilogram of bananas gives off about 1.1 kg CO2 from farm to fork? A ton of bananas packaged in Xtend packaging saves on average 13% waste (no more brown bananas!), representing 143 kg CO2 emissions saved. Offsetting that by the CO2 emissions of manufacturing the packaging, there is still a net savings of more than 108 kg of CO2 emissions per ton of bananas.

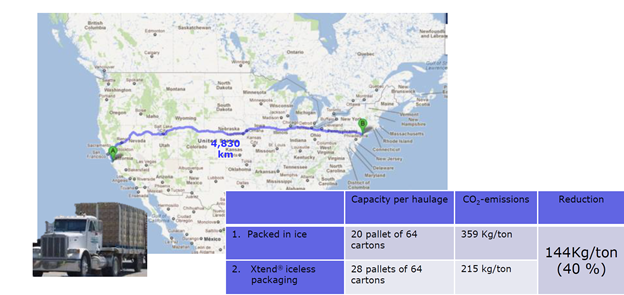

In many regions, broccoli is traditionally field-packed and then filled with ice before shipping. Ice takes up a lot of space and weight, and by replacing it with StePac’s MA/MH packaging, up to 33% more broccoli can be packed in the same container, with 30% less gross weight. If we compare the CO2 emissions from transporting broccoli from Salinas CA to New York by truck, the savings is around 144kg per ton of CO2 emissions, or 40%.

A major club store was able to reduce asparagus waste by 5% when moving from naked to StePac’s Xtend MA/MH packaging. A kilogram of green asparagus gives off about 2 kg CO2 equivalents, from farm to fork. A 5% waste reduction per ton of asparagus represents 50 kg asparagus saved and thus 100 kg CO2 emissions saved. Offsetting that by the emissions of the MA/MH package manufacturing, the final savings is still around 75 kg CO2 emissions per ton of asparagus.

Similarly, putting white asparagus from Peru in MA/MH packaging enabled it to be transported by sea freight as opposed to air freight, saving more than 95% of the CO2 emissions, or 5,538 kg of CO2 emissions per ton shipped.

Chinese importers are willing to pay a premium for high-quality blueberries and cherries, stimulating growth in these exports from Peru and Chile. Blueberry exporters automatically package 12 clamshells of blueberries in Xflow. The packaging film is highly transparent with zero condensation and more aesthetically appealing than preformed bags. The process saves up to 40% in use of plastic film in comparison to using preformed bags and is also more efficient and cost-effective.

Chilean cherry exporters use Xgo resealable lidding film for preserving the quality of cherries in long distance freight to China. This elegant packaging solution takes the value all the way to the end consumer. Each time the film is resealed to the tray after removing some of the cherries, the modified atmosphere redevelops and thereby continues to preserve their quality. Exporters and importers can rely on StePac for across-the-globe fresh produce preservation.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checkbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checkbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

Fill out this form so we can understand your needs and assess the best packaging for

you in a complimentary consultation. Required fields are marked with*